Wall-E Toy Design

During my Junior year in Multidisciplinary Engineering at Purdue University, I took a course called Toy Design. The course focused on the teaching the fundamentals of 3D modeling in Creo, basic circuit design, 3D printing, and simple mechanism design. As a final project for Toy Design, I teamed up with four other mechanical and multidisciplinary engineering students to design and manufacture a toy with at least 2 moving parts. Our team chose to make a mechanical push-action toy representing Disney’s Wall-E.

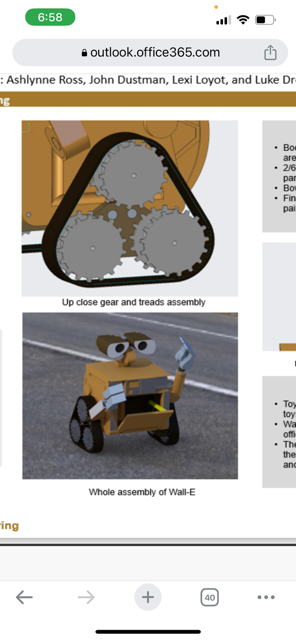

The team first created a 3D model of Wall-E using reference images from the Pixar movie. My contribution to the 3D model was producing all of the CAM skeletons for the 2 motion actuated parts. When the toy is pushed along a rigid surface, the treads actuate a CAM system inside Wall-E’s body that opens and closes his front hatch and tilts his eyes up and down. My other team members designed the individual 3D parts of Wall-E in CAD.

I then prepared the 3D CAD files to be 3D printed and post processed them by sanding and priming. I hand painted the weathered rust texture on the parts and details like the eyes using acrylic paint. I then completed the final of the mechanisms and validated their functionality.

See video demo of finished Wall-E Toy

This project enhanced my skills in 3D modeling in Creo, creating motion skeletons, 3D printing, and post processing. More importantly, it taught me fundamentals of team communication and project management. Our Wall-E push action toy won the Popular Choice Award at Purdue’s Spring 2023 ME Toy Fair and it would not have been possible without coordinated communication and a multidisciplinary approach to problem solving.